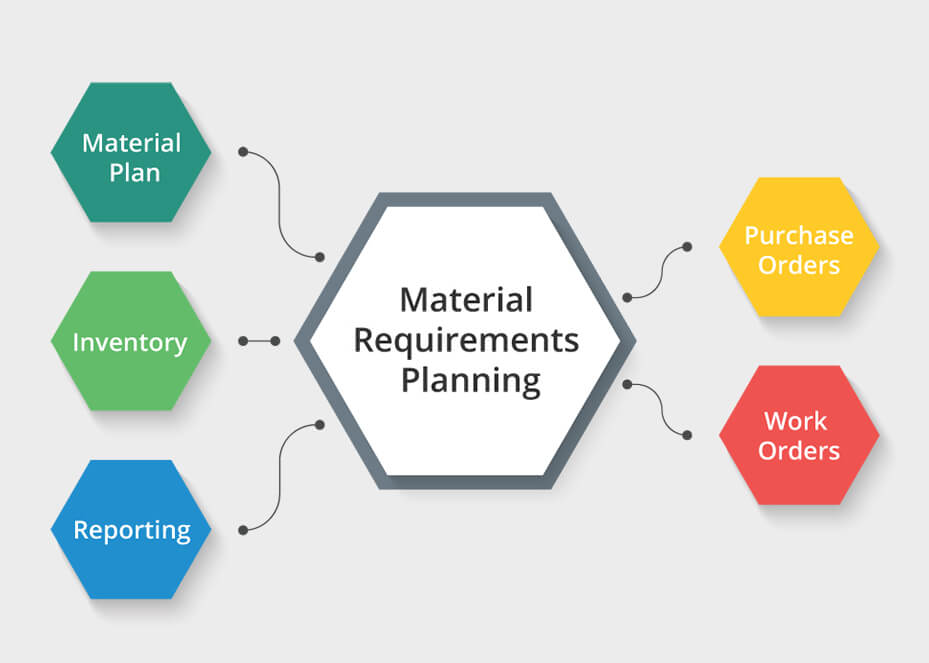

What is MRP in Tally ? Material Requirement Planning (MRP) Module in Tally is a production planning in an organization used to manage Manufacturing Processes. MRP helps you quickly take into account and evaluate your demand, based on your open Sales Orders and Sales Projection.

MRP Module in Tally gives complete overview of Stock availability of raw material for indent requsted from stores. MRP module in Tally process Sales Orders wise indents for non available BOM Products.

Manufacturing Tally Software focuses on maintaining the lowest possible level of Inventory and plan Manufacturing Activities, Delivery Schedules, and Purchasing Activities.

Material Requirement Planning (MRP) is an add-on module to Tally.ERP 9, which allows the user to work out the production and purchase requirement based on the Tally data as to sales orders/ sales plans, pending purchase orders, minimum stocks, Reorder level etc worked with the Bill of Materials for finished Goods and semi finished goods.

The Material Resource Planning(MRP) Module can help you eliminate Purchasing and Scheduling problems. It is designed to simplify and speed up the work processes of Purchasing, Inventory, and Production Managers, enabling them to plan more effectively in Tally.ERP 9.

Tally Manufacturing module supports stock and sales visibility with complete control on finished goods stock levels and raw material purchase order in tally.